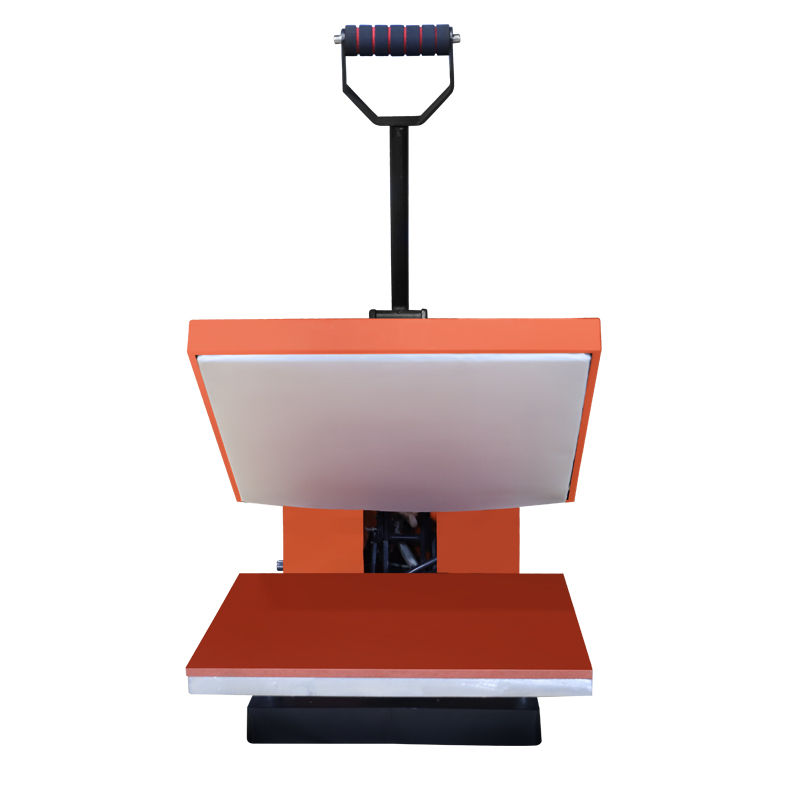

OEM Supply Hat Heat Press Machine - 15×15 Clamshell Heat Press Machine – Asiaprint

OEM Supply Hat Heat Press Machine - 15×15 Clamshell Heat Press Machine – Asiaprint Detail:

Technical Parameters

| Brand Name | Asiaprint |

| Voltage(V) | 220/110V |

| Temperature range(°C) | 0-399 |

| Time control(S) | 0-999 |

| Printing area(CM2) | 38X38(15”X15”) |

| Power(KW) | 2.2kw |

| Gross weight(KG) | 32kg |

| Packing Dimensions(CM) | 72*48*39cm |

| Warranty | 1 Year |

| MOQ | 1 Set |

Feature

1. Temperature controller with digital display (tolerance: ±2), electronic time controller and information display panel ensure the operational convenience

2. Featuring high strength, smooth texture,good hot-stamping effect and easy cleaning.

3. Calibrated thermostat before ex-factory, temperature error under ±2°C.

4. Bottom surface equipped with temperature-resistant silica gel plate can help deliver perfect transfer-print products.

5. Up and down heating simultaneously,makes the heating more uniform.

6. Independent research and development,over ten years manufacture experience,high quality assured.

7. Easy pressure adjustable with pressure wheel.

8. Classic model,fashional and simple outline,various color to select.

Heat Transfer Temperature And Time Settings

1. Sublimation heat transfer – Temperature: 220 C, Time: 20 seconds

2. film heat transfer – Temperature: 160 to 180 C, time: 8 to 10 seconds

3. foam Tang – temperature: 140 ~ 160 C, time: 5-8 seconds

4. hot drilling – temperature: 180 C, Time: 10 to 12 seconds

OEM/ODM

We have a professional after-sales team that can provide video tutorials for assembling machines and solving machine problems online 24 hours.

High production capacity and a short delivery time.Compare with the delivery time of roller heat press machine, the peer needs more than 20days, and we can complete it in 15 days.

Product detail pictures:

Related Product Guide:

Knowledge Of Intelligent Automatic Roll To Roll Heat Press Machine

We thinks what prospects think, the urgency of urgency to act from the interests of a client position of theory, allowing for greater high-quality, reduced processing costs, rates are much more reasonable, won the new and previous consumers the support and affirmation for OEM Supply Hat Heat Press Machine - 15×15 Clamshell Heat Press Machine – Asiaprint, The product will supply to all over the world, such as: Hamburg, luzern, Czech, Look forward to the future, we will focus more on the brand building and promotion . And in the process of our brand global strategic layout we welcome more and more partners join us, work together with us based on mutual benefit. Let's develop market by fully utilizing our comprehensive advantages and strive for building.

We have been cooperated with this company for many years, the company always ensure timely delivery ,good quality and correct number, we are good partners.