Operation Step

1. Make sure you connect electricity three phase power well. Press "Blanket Enter" button, blanket will get closer to drum and the "Blanket Action Indication" light on and alarms at the same time.After blanket completely cling to the drum, the "Blanket Action Indication" stop alarming. Press the “start” button, the machine will be running.

2. Set the "FREQ SET"(Speed)18 rounds.Can not lower than 10.Otherwise the motor will be easily broken. (REV is the reversal, FWD is forward, STOP/RESET is outage.Machine EX-factory settings is "FWD".No need to change it.FREQ SET is frequency setting)

3. At the first time, you will need to preheat machine as below:

1) Set the temperature to 50 degree Celsius, when it heated up to 50 degree, await 20 minutes.

2) Set 80℃, after heating up to 80 degree, await 30 minutes.

3) Set 90℃, after heating up to 95 degree, await 30 minutes.

4) Set 100℃, after heating up to 100 degree, await 30 minutes.

5) Set 110℃,after heating up to 110 degree, wait for 15 minutes.

6) Set 120℃, after heating up to 120 degree, wait for 15 minutes.

7) Set 250℃,directly heat up to 250℃

Let the machine run with 250℃ without doing heat transfer for 4 hours.

4. Second time you can set temperature to be what you need directly. If you need 220℃, set it 220℃ and 15.00 rounds.

After temperature heats up to 220 degree, press "Pressure Switch" button, 2 rubber rollers will press blanket to make the blanket cling to drum. (Tips: machine needs to connect with an air compressor)

5. If the fabric is too thin, please run with protection paper to prevent ink getting into blanket.

6. Successful sublimation requires the suitable time, temperature and pressure. The thickness of fabric, sublimation paper quality and fabric species will affect the sublimation effect. Try small pieces in various temperature and speed before commercial production.

7. At the end of working day:

1) Adjust speed of drum to be faster to be 40.00 rounds.

2) Press "Automatic Shut down". The drum will stop heating up and the drum will not run until the temp. is 90℃.

3) "Stop" button can be pressed when EMERGENCY situation happened. The blanket will automatically separate from drum.The distance of blanket and drum is maximum 4cm. If you have some urgently and need to leave from factory at once, you can press "stop" button as well.

NOTICE: Make sure blanket completely separated from drum.

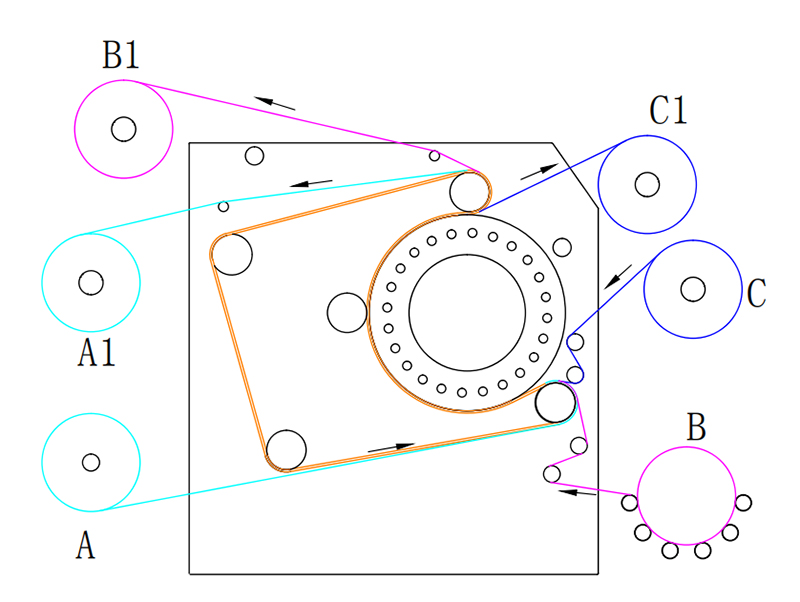

Working Flow

Operation cautions

1. The machine speed can not lower than 10, otherwise the the motor will be easily broken.

2. When suddenly power cut off, have to separate blanket from drum manually to prevent from being burning out. (must be check and ensure it separated totally)

3. Automatic blanket alignment system, you need to do the alignment manually when the automatic system broken.

4. When the machine start heating, the drum must be running to prevent blanket burn out.It would be better that worker is there in process heating.

5. In high temperature condition, such as emergency stop or power outage, separate blanket from drum at once.

6. Bearings should be greased “grease oil” every week, which guarantee the normal rotation of the bearing.

7. Keep machine clean especially fans,slip ring and carbon brush etc.

8. It is normal that indicator light flash and buzzer ring when blanket is entering.During sublimation,the light of indicator flash and alarm sometimes because blanket alignment works.

Post time: Apr-01-2021