How to operation DTF Printer?

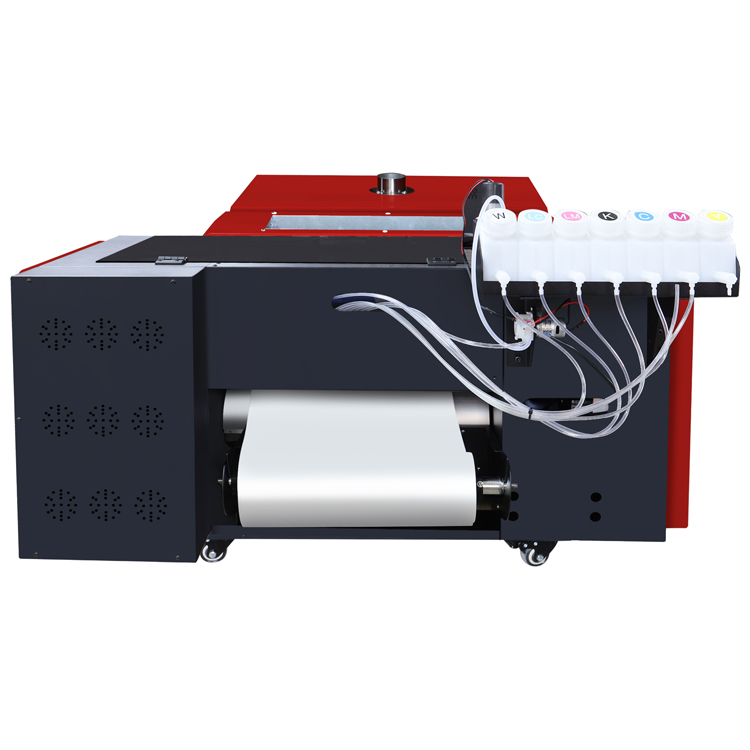

DTF technology has been around for several years, but it became very common in the last year. The essence of this technology is to use textile pigment ink to directly print on a special PET film. After printing, the film enters the powder shaker, sprays special powder on the film, and then the film is dried after spraying, and then the film with the print pattern is wound on the receiving device . This technology allows you to print images at high speed without placing the product on the desktop alone, you just need to place the film, create a layout with the image and start printing.

Operation Video

More types of Printer machine operations videos are also in the channel.Welcome to click on the video of heat press machine and follow our youtube channel

Specification

| Model | XP600 |

| Printhead | Double |

| Type | waterbase pigment ink |

| RIP | Photo Print |

| Ink colors | 5 Colors (C,M,Y,K+W) |

| Max Print size | 300mm |

| Machine Dimension | 1650(L)*770(W)*850mm(H) |

| Gross Weight | 200KG |

| Voltage | 110-220V,50-60Hz |

| Media | PET film |

| Function | Flouring&Drying Powder |

| Dry system | Automatic constant temperature |

Highlights

DTF printer comes with dual Eps XP600 print heads. One is for white ink and another is for color ink CMYK. The DTF printer used eco pigment ink which is much economic than DTG ink. It accept all type facbric heating transfer printing with vivid design.

DTF printer was made by CNC finish-milling. It has perfect precision. And we used Hiwin linear guide rail on the printer. Make it has perfect printing precision.

DTF printer comes with white ink automatic circulation and stirring system. Ensure the white ink quality and avoid block print nozzle effectively.

Our Advantage

1) Over 20+ years experience.

2) Top quality domestic components.

3) High quality manufacturing group,complete quality control system.

4) Customized design ability.

5)Fast delivery day,full of after-sales service.

Post time: Sep-11-2021