Multi-Function Jersey Small Roller Heat Transfer Press Sublimation Machines

Specification

| Machine Name | Calendar |

| Printing/Roll Width | 1700MM/67Inch |

| Roller diameter | 210MM /8.27Inch |

| Voltage | 220/380/420 Three-phase |

| Other Voltage | Custom voltage by your special order |

| Rated output | 11KW |

| Speed | 0-6M/Min |

| Weight | 1020KG |

| Packing Size | 248x100x165CM |

| Feeding Method | Top feeding |

| Other Size | Available |

| Air Compressor Required | Required |

| Blanket Material | Nomex:High Temperature Resistance |

| Drum Surface | Chrome:High hardness and abrasion performance |

| Drum | Oil 100% |

| Temperature Range | 0-399℃ |

| Scope Of Delivery | Roller heat transfer machine,Power cable without plug,some electronic spare parts for free |

| Note | Custom size by your special order |

| Customized machine to work with different power supplier | |

| Warranty | One Year |

| MOQ | One Set |

Features

1. Roller surface with Teflon coat, high hardness, wear resistant, anti-sticking.

2. Digital temperature and speed hardness, wear resistant, anti-sticking.

3. Oil heating, temperature uniformity (±1-2°C) no deviations of color.

4. Using imported heating pipes,heat evenly,durable; imported blankets which is not easy to deviate.

5. The blanket is detachable,and not easy to burn; with belts putting device for installing and fixing the belts.

6. Can let the blanket to be automatic correction, ensure the normal orbit, make the efficiency of heat transfer enhance maintain the transfer quality guaranteed.

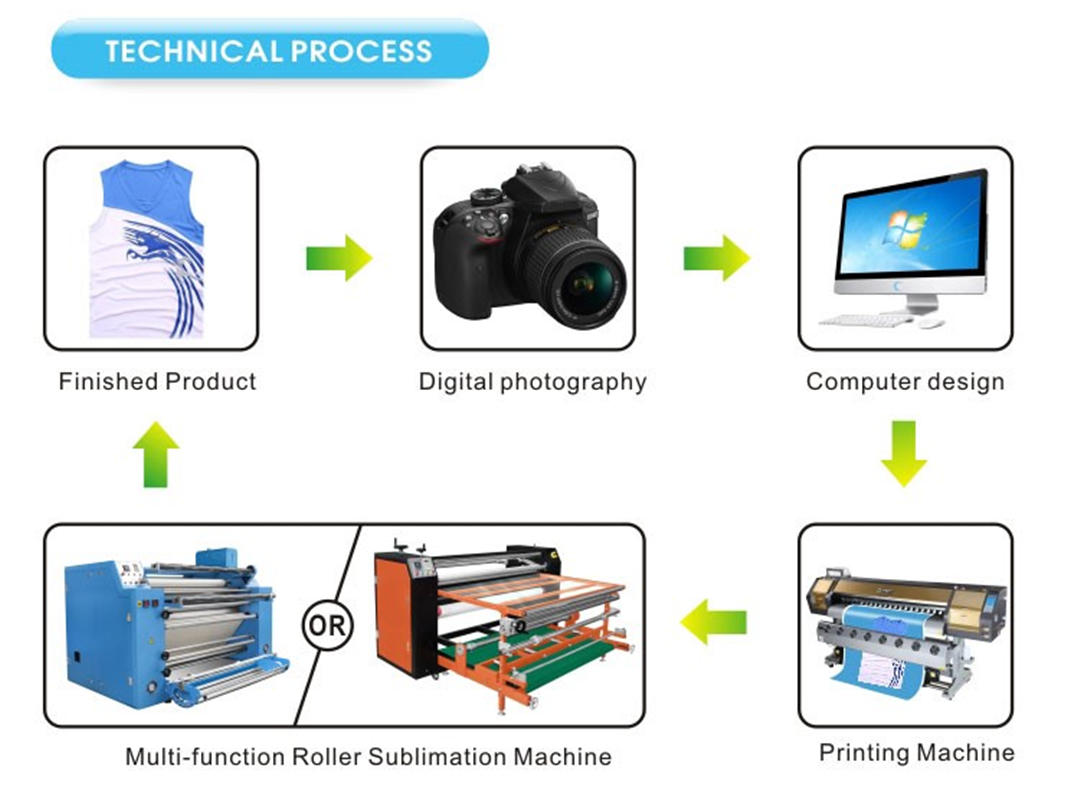

Product Application

Calendar Heat Press Machine is suitable for Clothing, toys, shoes, bags, home textile, textile furniture's sublimation printing. It is widely used to produce the finished products, cut-part, rolled fabric & narrow fabric etc.

Operation

1, Check that all screws in mainframe are loose or not, tighten if loose.

2, The whole machine should be set at level with enough capacity; wood frame to overhead the sliding wheel and level direction is preferred.

3, Matched load leakage circuit breaker separately on this machine with 3×6×6+1×4×4 international power wire. The crust of machine must be earthed separately.

4, Keep the equipment in level while installation. Use two section 160×160×700(length) of bed timber under inner side of two wheel. Use level instrument to check if the machine is level or not.

5, When the working table is installed, the height must be consistent with feeding blanket and level. The paper feeding (put in) shaft and cloth feeding (put in) shaft must be of the same level with heating tank.

Package And Services

1. All our machines will be well packed by the foam rubber first, then they will be put in the carton case with shipping mark on the surface.

2. we must try our best to make sure that all the machines will be conveyed to you with no damage.

3. Any problems happened while transportation is responsible for us.

4. Life-long on-line technical support.

5. Provide free parts when problems occur within one year.

About the after-sales service

A. If the calendar roller heat press machine has problem, the client can take a picture or video to the technician.

B. The technician will teach the client to fix and operate the roller heat press machine through the internet.

C. And we will ask the client to send back the board which is wrong to check it.

D. Believe us. The technician is full of experience, and the sales also keep in touch with the client.