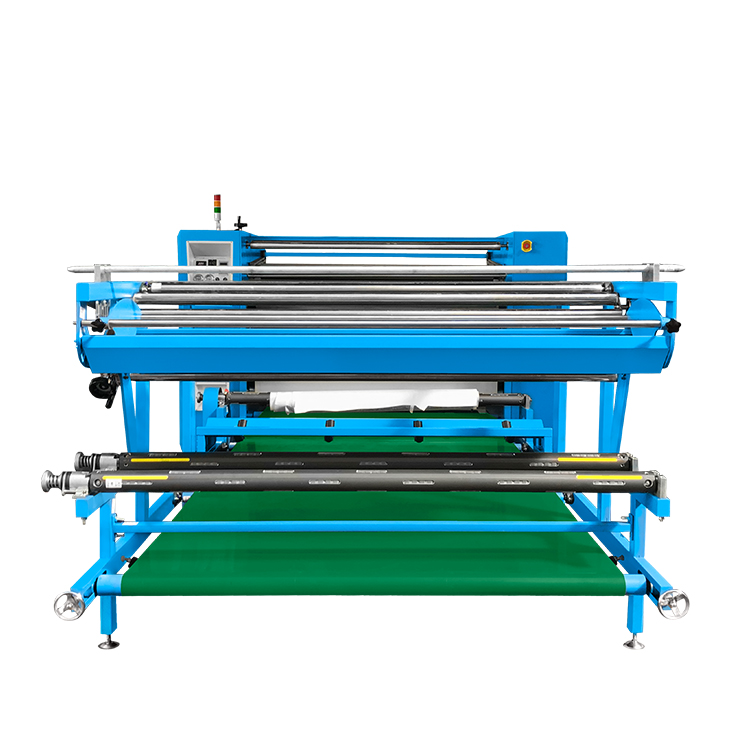

Roll To Roll Heat Transfer Printing Machine

Description

Heat press machine which can be used to press shirt and other materials as long as it is flat. Works by using electricity to heat the heating element at the top, and then when lowered will press the T-shirt/other materials powerfully and making printing ink, plastisol, rubber, sublime, transfer paper, polyflex, etc stick well to the shirt material.

Highlights

1.Digital temperature and time controller

2.Adjustable press pressure

3.High power quick heat plate.

4.High efficient double station machine

5.Heat plate automatically rise when transfer is done.

6.Optional laser positioning system and foldable workbench are available.

|

Item |

JC-26B |

||||

|

Roller width(MM) |

1800 |

2000 |

19000 |

2000 |

2000 |

|

Roller Diameter(MM) |

800 |

800 |

1000 |

1000 |

1200 |

|

Power(KW) |

85KW |

||||

|

Weight(KG) |

4000KG |

||||

|

Voltage(V) |

380V

|

||||

|

Temperature range(℃) |

0-260 |

||||

|

Time range(S) |

0-999 |

||||

|

Warranty |

1 Year |

||||

|

MOQ |

1 Set |

||||

|

Package |

Wooden case |

||||

|

Color |

Black+Customized |

||||

Features

1.Prcise control of temperature and time .It is humanization design and easy to use.

2.Drum is covered by blanket with 75%,temperature zone can run and save electricity for very long time.

3.When the blanket is out of the position,it can be corrected automatically and prevent the blanket movement from affecting printing result.

4.In case of power cut;increase security and convenient design of manual felt returning device to protect the service life of the blankets.

5.The roller for the used sublimation paper on the shelving unit it to take away,it can save mote heavy working and let the worker do easier.

6.Deal with smoke and gas produced in the transfer printing process,work more efficiently.

7.Reduce the fume insides chassic,long service time

8.If the products are thin and need more presssure,please press"pressure" button to active the air cylinder.

Our Advantage

1) Over 19+ years experience.

2) Top quality domestic components.

3) High quality manufacturing group,complete quality control system.

4) Customized design ability.

5)Fast delivery day,full of after-sales service.

Packaging Details

Packed in Rigid Standard Export Wooden Case